Three myths about commercial spc flooring

Oct 17, 2022|

Oct 17, 2022| View:358

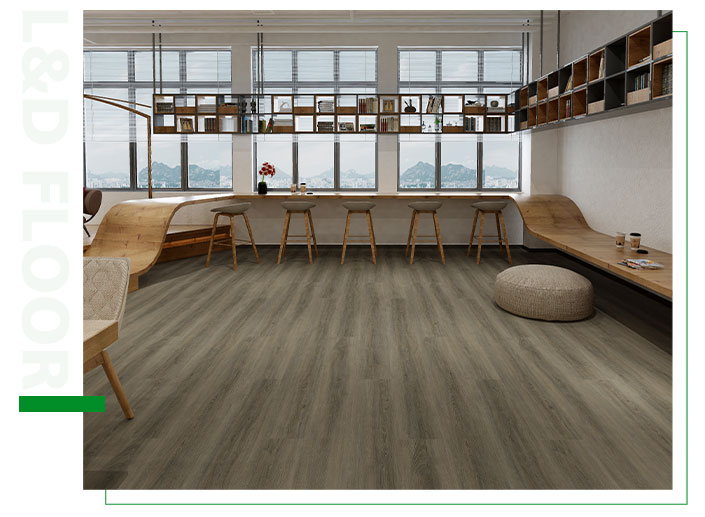

View:358Commercial spc flooringis a type of laminate floor that is also made from polyvinyl chloride materials, processed by commercial spc flooring suppliers, hot-pressed by high-temperature calendering, coated with color film, PVC abrasion-resistant layer, and cooled by UV process, finally, commercial spc flooring suppliers use the floor cutting and slotting process to complete the floor production.

Here are three misconceptions about commercial spc flooring:

1. commercial spc flooring does not fail to burn

Some people think that the fire to burn commercial spc flooring, see can burn up, burn up is not fire, do not burn up is flame retardant. In fact, the national standard for fire grade of commercial spc flooring is Bf1-t0. According to the national standard, non-combustible materials are classified as fire grade A, such as stone, face brick, etc. . The BF1-T0 standard contains a 10mm diameter cotton ball, dipped in alcohol, placed on a PVC floor, and burned naturally. Once the cotton ball is burned, commercial spc flooring suppliers measure the diameter of the burned commercial spc flooring trace, such as less than 50mm, it's the BF1-T0 flame retardant standard, not whether it burns.

2. commercial spc flooring“Wear-resistant” is not“Wear-resistant”

When people ask about the service life and wear resistance of the commercial spc flooring, they will take out a knife or a key and scratch the surface of the commercial spc flooring. In fact, commercial spc flooring suppliers do not simply test the abrasion resistance of commercial spc flooring by using a sharp tool to scratch the surface. Instead, it uses a flat-bottomed circular grinding plate to grind the floor under a pressure of 1 kg, and after a number of turns of the grinding wheel, commercial spc flooring suppliers use a flat-bottomed circular grinding plate to grind the floor under a pressure of 1 kg, the number of revolutions at which the wear-resistant layer on the floor surface is worn out to expose the base layer. The rotation of this node is a measure of the wear resistance of the commercial spc flooring. For example, composite floor rotation national minimum standard of 1500 rpm.

3. “Sniffing smells” is not“bad for the environment.”

Commercial spc flooring itself is formaldehyde-free, commercial spc flooring is not allowed to use formaldehyde in the production process, commercial spc flooring suppliers specifically state that qualified commercial spc flooring formaldehyde content will not exceed the prescribed standard, and may have the smell of fragrances and additives, it Won't hurt People's bodies, and it won't make people feel uncomfortable.

Commercial spc flooring is now widely used as a decorative material, and more and more families are choosing to use it. As a professional commercial spc flooring supplier, we have a high-quality product line and a wide variety of styles to choose from to provide you with more services.